Technicians

Technician

Cooperation

Communication

1.Anti-interference photoelectric switch

Photoelectric switch is short for photoelectric control switch,it detects the existence of object via electronic signal,is mainly used for checking the position of the bottle/cap/working station etc on belt conveyor. Besides metal,all that can reflect light can be checked.New photoelectric switch has the advantages of small volume, multiple functions, long service life, high precision, fast response speed, long detection distance and strong anti-interference of light, electric and magnet.

Photoelectric switch is short for photoelectric control switch,it detects the existence of object via electronic signal,is mainly used for checking the position of the bottle/cap/working station etc on belt conveyor. Besides metal,all that can reflect light can be checked.New photoelectric switch has the advantages of small volume, multiple functions, long service life, high precision, fast response speed, long detection distance and strong anti-interference of light, electric and magnet.

2.Anti driping and splash filling nozzles

We adopt a unique patented technology for the filling head,make it suitable for filling various viscous material, no drip, no splash, no drawing.suitable for machine of which speed reach 6000 bottles per hour. Adopts SS316 stainless steel material, the filling temperature ranges from - 20 DEG C to about 200 DEG C, controllable pressure 0-1.6MPa. the filling heads can be used in cooperation with the servo motor, can effectively avoid the inaccurate filling volume, and difference of filling volume caused by all the filling heads fill simultaneously.

We adopt a unique patented technology for the filling head,make it suitable for filling various viscous material, no drip, no splash, no drawing.suitable for machine of which speed reach 6000 bottles per hour. Adopts SS316 stainless steel material, the filling temperature ranges from - 20 DEG C to about 200 DEG C, controllable pressure 0-1.6MPa. the filling heads can be used in cooperation with the servo motor, can effectively avoid the inaccurate filling volume, and difference of filling volume caused by all the filling heads fill simultaneously.

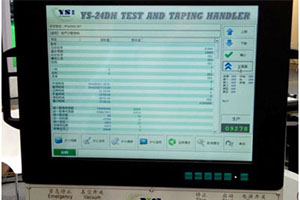

3.Advanced touch screen

The touch screen is installed on the front part of the display device,can be touched by finger or other objects.Via PLC,the touch screen can control all the mechanical equipment and related assistant equipment including visual inspection camera / code machine. It can display the output / qualified rate / rejection rate of the production line, and power consumption/gas consumption of each independent equipment , as well as date of maintenance, maintenance tips etc.

The touch screen is installed on the front part of the display device,can be touched by finger or other objects.Via PLC,the touch screen can control all the mechanical equipment and related assistant equipment including visual inspection camera / code machine. It can display the output / qualified rate / rejection rate of the production line, and power consumption/gas consumption of each independent equipment , as well as date of maintenance, maintenance tips etc.

4.Visual inspection

The visual detection system consists of camera, lens, light source,can replace the manual checking for bar code character, cracks, packing, completeness and sunkeness of the surface.The application of visual inspection system can effectively improve yield and quality of the production line,also greatly reduce the labor and costs, while preventing error judgement caused by human eye fatigue.

The visual detection system can detect minimum 3 microns, takes only 3 ms, and can also detect the liquid level, whether the bottle cap body is damaged or not, whether there is suspended solids,and exterior detection (shelf-life, bar code), as well as other quality detection.

The visual detection system consists of camera, lens, light source,can replace the manual checking for bar code character, cracks, packing, completeness and sunkeness of the surface.The application of visual inspection system can effectively improve yield and quality of the production line,also greatly reduce the labor and costs, while preventing error judgement caused by human eye fatigue.

The visual detection system can detect minimum 3 microns, takes only 3 ms, and can also detect the liquid level, whether the bottle cap body is damaged or not, whether there is suspended solids,and exterior detection (shelf-life, bar code), as well as other quality detection.

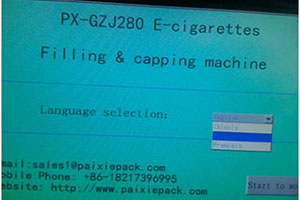

5.Multi-language

There are 8 major languages in the world for option. In order to allow customers to have a better understanding of products and services information of our enterprise , we developed and set 8 kinds of language in the touch screen,including English / French / Spanish / Arabic / Russian / Korean / Chinese according to the language used by our target customers

There are 8 major languages in the world for option. In order to allow customers to have a better understanding of products and services information of our enterprise , we developed and set 8 kinds of language in the touch screen,including English / French / Spanish / Arabic / Russian / Korean / Chinese according to the language used by our target customers

6.Electrical cabinets accord with the safety and technical standards of Europe and the United states:

According to safety standards of Europe and the United States,it’s handmade by experienced electrical engineers,it has advantages of canonical label, rational planning of lines, the electrical components are placed accord with the international practice and habits, passed the CE certification for safety and quality system of EU

According to safety standards of Europe and the United States,it’s handmade by experienced electrical engineers,it has advantages of canonical label, rational planning of lines, the electrical components are placed accord with the international practice and habits, passed the CE certification for safety and quality system of EU

Technical Team